With climate change regularly in the spotlight and countries under increasing pressure to reduce their greenhouse gases, legislation governing waste, energy consumption, and harmful emissions continues to tighten, forcing manufacturers to conform or face fines and financial penalties.

Carbon emissions from end-of-line packaging processes are typically very high due to the common use of heat shrink tunnels. But this can be resolved through the introduction of stretch wrap technology.

As a cold-wrap solution, stretch wrapping not only saves manufacturers over 90% on energy costs, but it also ticks all the boxes when it comes to environmental legislation.

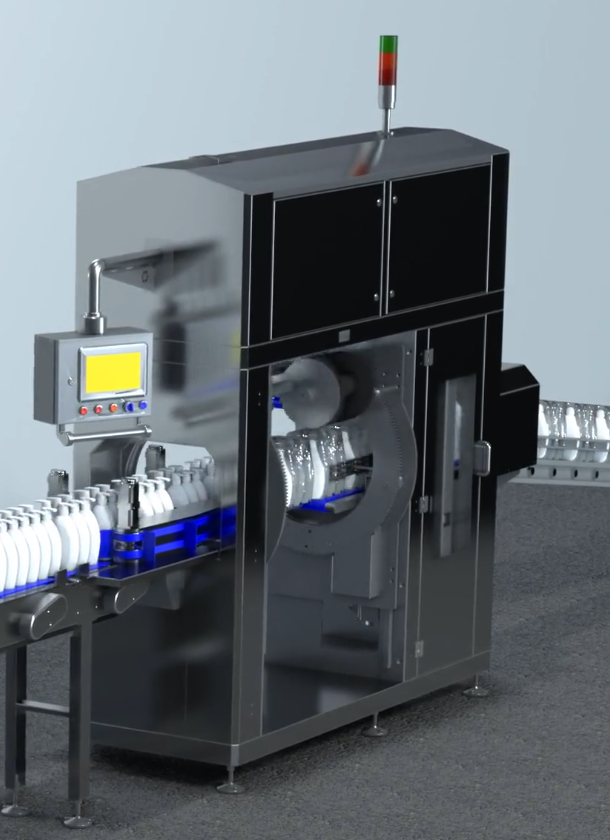

Here is an overview of the current legislation affecting FMCG manufacturing and how YEPCO’s Eco Wrapper can help…

Climate Change Levy

What is it? An environmental tax for businesses, public sector bodies, agriculture, and industrial users to encourage energy efficiency and reductions in carbon emissions. It applies to electricity, natural gas, LPG, and solid fuels.

When does it come into effect? Now – since 2001

What does it affect? Energy prices – levy charged per unit of energy use

What will mitigate the effects? Use less energy and lower carbon emissions

How will YEPCO solutions help? The Eco Wrapper uses over 90% less energy as it is a cold-wrap solution

Plastics Tax

What is it? An environmental tax which applies to businesses who manufacture or import ≥10 tonnes of finished plastic packaging components per year into the UK. It targets plastic packaging that contains less than 30% recycled plastic. Packaging that contains ≥30% recycled plastic (by weight) is exempt from the tax.

When does it come into effect? Now – since 2022

What does it affect? Plastic packaging that contains <30% recycled content

What will mitigate the effects? Use plastic that contains 30% PCR content

How will YEPCO solutions help? The Eco Wrapper uses film with 30% PCR content

Extended Producer Responsibility (EPR) Fees

What is it? A policy which charges producers a fee per tonne of packaging material used, with different packaging types attracting a set fee based on their environmental impact. Packaging types that are easily recycled will be charged at a lower fee per tonne than those that are more difficult to recycle.

When does it come into effect? October 2025

What does it affect? Net packaging use

What will mitigate the effects? Use less packaging and recycle more

How will YEPCO solutions help? The Eco Wrapper uses up to 70% less plastic and the linear, low density, polyethylene is 100% recyclable. Because there is no heat in the process, biodegradable and compostable films can also be used.

Emissions Trading Scheme: Energy-from-Waste

What is it? An expansion of the current Emissions Trading Scheme to include energy-from-waste and waste incineration. Production facilities will be required to purchase carbon allowances to offset their emissions, which will add a cost to their processes.

When does it come into effect? A phased approach between 2026 – 2028

What does it affect? Plastic incineration

What will mitigate the effects? Recycle more

How will YEPCO solutions help? Like for EPR above, the Eco Wrapper uses up to 70% less plastic and the linear, low density, polyethylene is 100% recyclable. Because there is no heat in the process, biodegradable and compostable films can also be used.

Carbon Tax

What is it? A tax encouraging manufacturers to reduce their carbon footprint.

When does it come into effect? To be confirmed

What does it affect? Carbon footprint

What will mitigate the effects? Reduce carbon emissions

How will YEPCO solutions help? The Eco Wrapper produces up to 70% less carbon

If you’d like any further information on how our sustainable secondary packaging solutions can help your manufacturing business to conform to current environmental legislation, please get in touch.