Sustainable innovation at the core

YEPCO delivers advanced end-of-line packaging machinery powered by cold wrap technology, a sustainable alternative to traditional shrink wrap systems.

Our stretch wrapping machines eliminate the need for heat, reduce plastic waste, and consume over 90% less energy, making them safer, cleaner, and far more efficient. Designed for speed, consistency, and flexibility, they help manufacturers cut costs, lower carbon emissions, and avoid environmental levies such as the Plastics Tax.

By switching to cold wrap, businesses are streamlining production, protecting products during transit, and taking a major step towards their sustainability goals.

Talk to our experts and see how you can make the switch today.

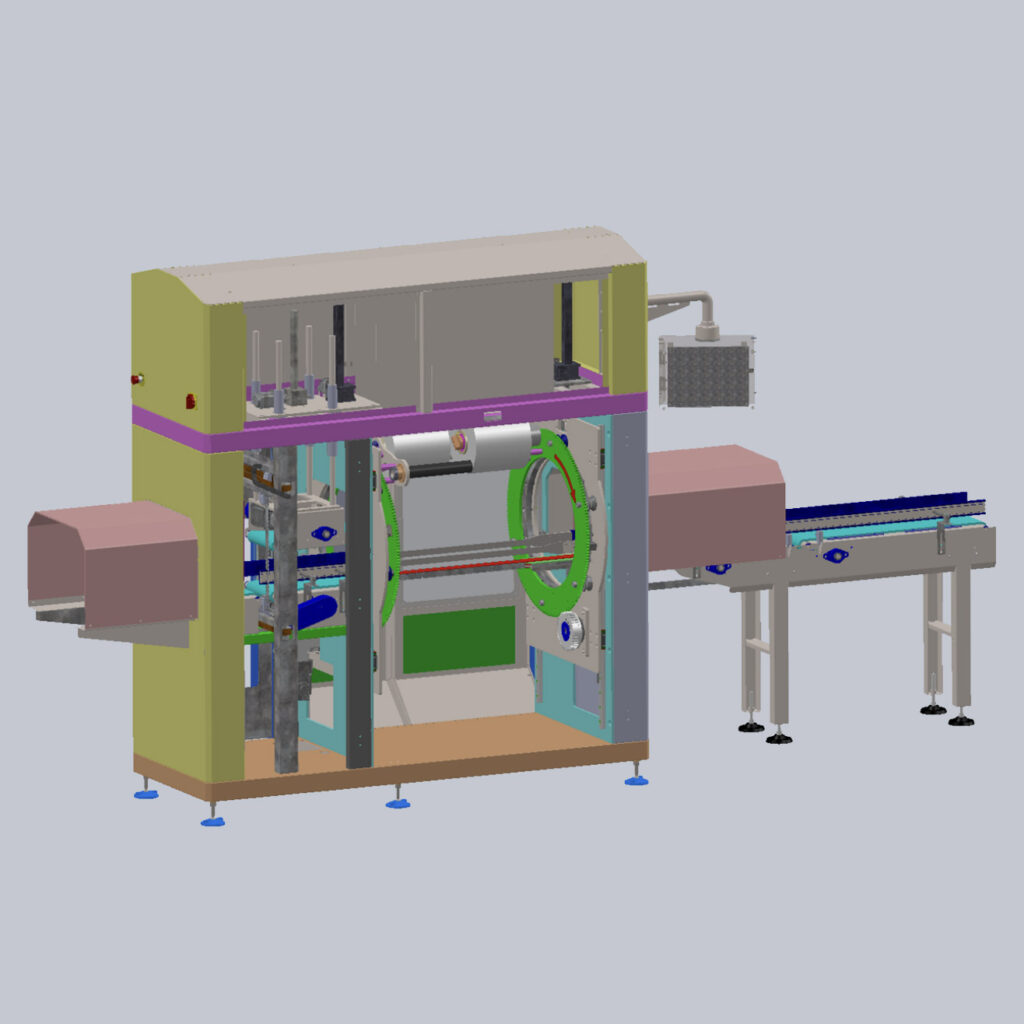

How does it work

YEPCO’s secondary packing machines work by utilising the elasticity of thin, recyclable, stretch films. Reels of film are mounted on a rotating turret that wraps the film tightly around collations, stretching the film as it wraps.

YEPCO’s secondary packaging machines use cold wrap technology with thin, recyclable stretch film to secure products, without the need for heat. Reels of film are mounted on a rotating turret, which stretches and wraps the film tightly around each collation. Film tension and overlap are precisely controlled to maintain pack integrity, regardless of product shape, size, or fragility. This makes the system ideal for wrapping jars, pots, cartons, cans, bottles, aerosols, and more. Because no heat is used, cold wrap packaging is safer, more energy-efficient, and better suited for temperature-sensitive or flammable goods.

The simplicity of the system also ensures high uptime, low maintenance, and consistent performance across a wide range of manufacturing environments.

Stretch wrap vs. shrink wrap

Lower running costs

Save over 90% on energy costs

Cut carbon emissions

Reduce carbon emissions by up to 70%

Reduce plastic usage

Up to 70% less plastic consumption by using thinner films

Cardboard weight reduction

30% lighter cardboard packaging or remove cardboard completely

Faster line speeds

Ability to speed up or slow down lines to suit production requirements

Service

reliability

Uptime performance of over 98%

Ease of

upkeep

Efficient maintenance & servicing

Consistent pack quality

No heat-induced pack blistering or damage

Environmental compliance

Avoid high environmental taxes such as Climate Change Levy and the Plastics Tax

Heat

resistance

Particularly well-suited for temperature-sensitive or flammable goods like aerosols

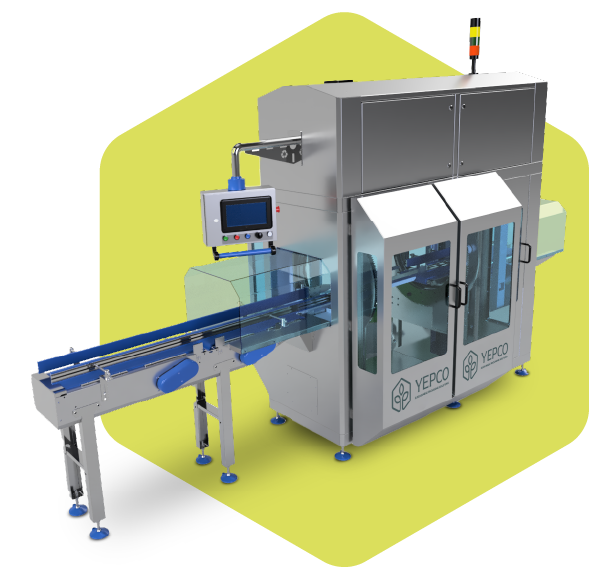

Scalable, Sustainable Packaging with the YEPCO Eco Wrapper

YEPCO’s proven Eco Wrapper machine offers FMCG manufacturers a sustainable, scalable solution for modern end-of-line packaging. Designed to meet the demands of 21st-century production, it uses advanced digital automation to deliver flexible, high-performance secondary packaging across a wide range of product types.

With rapid line changeovers, minimal downtime, and remote maintenance capabilities, the Eco Wrapper improves operational efficiency and helps future-proof your packaging process.

Our custom-engineered solutions accommodate packaging with or without cardboard trays, ensuring complete compatibility with your manufacturing needs. Plus, with significantly lower energy consumption and reduced material use, YEPCO helps you cut costs while progressing toward your Net Zero and sustainability goals.