Sustainable stretch wrap technology is now transforming secondary packaging for FMCG manufacturers, but the concept was actually born back in the 1990s by visionary Peter Johnson.

A frightening incident at an aerosol production plant

After a frightening incident at an aerosol production plant where a batch of high pressurised aerosol tins got stuck in the heat tunnel and exploded, a group of scientists and engineers were tasked with eliminating heat from the end-of-line wrapping process. Although nobody was injured during the incident, it clearly highlighted the dangers of using heat tunnels for high-risk product types.

Peter Johnson acquired the patents for this new technology

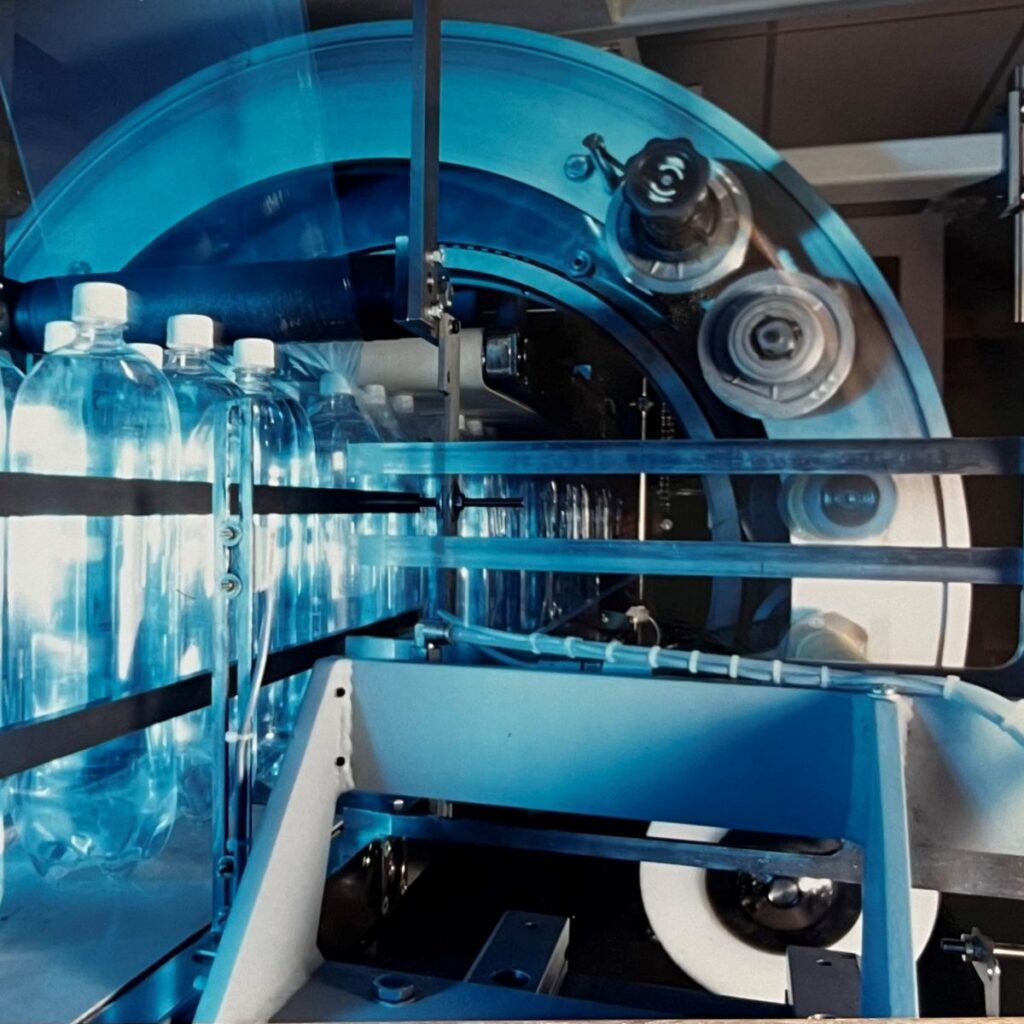

Peter Johnson acquired the patents for this new technology and after a period of design and development, he revealed his stretch wrapping prototype and trialled it with Huddersfield-based drinks company, Ben Shaws, wrapping 2L fizzy bottles of pop. The trial was a huge success, but despite this, the prototype machine needed a little more development to make it commercially viable, so Peter went back to the drawing board.

Electricity prices started to rise sharply

At the end of the 1990s and early in the 2000s, things started to change that would make Peter’s stretch wrap machines much more viable. Electricity prices started to rise sharply and packaging waste was becoming a big issue globally.

In 1998, the Waste Framework Directive was introduced by the European Commission which set out firm policies on waste disposal. FMCG manufacturers and retailers were encouraged to find ways to reduce, reuse and recycle, and prevent waste from going to landfill.

The leaders in the food and beverages industry decided to join forces to tackle these new challenges and subsequently formed the first Courtauld Commitment – a voluntary agreement to reduce the carbon and wider environmental impact of the UK food and drink sector.

The machine’s benefits finally made it commercially viable

This firm commitment to waste reduction and the need to reduce energy usage, were just what the stretch wrapper needed to bring it back into the limelight. The machine’s benefits of using less plastic packaging, and running at significantly lower running costs, finally made it commercially viable.

TrakRap had refined stretch wrap technology

Fast forward a few years and Peter Johnson’s company, TrakRap, had refined stretch wrap technology and the machines were being used by a wide range of customers packaging yogurts, frozen ready meals, pet food, pharmaceuticals, household products, and much more. The future of stretch wrapping was bright!

YEPCO acquired the assets from Eco Pack Technologies

In 2022 Eco Pack technologies, an American owned company, acquired the assets from Trak-Rap and in 2025 YEPCO acquired the assets from Eco Pack Technologies.

Today, the technology is in the expert hands of the team at YEPCO, who have a shared passion for smart engineering, sustainable packaging, and protecting the environment. Thanks to their hard work and determination, the stretch wrapper is not only commercially viable, but it’s a commercial ‘no brainer’, saving manufacturers over 90% in energy costs and up to 70% in plastic usage compared to shrink wrapping.

Interested in learning more? Email us at hello@yepco.uk